Read menswear blogs long enough and you’re sure to come across something you really like, but can’t find anywhere. A few years ago, I read about Simon Crompton’s bespoke eyewear sleeve. Made by Alfred Dunhill, it was saddle stitched from green crocodile leather. I looked around for something similar, but everything was either too expensive or not nearly as handsome.

A few months ago, however, when Chester Mox loaned me some samples from their new line, it dawned on me that they’d be perfect company for this sort of thing. Bellanie – the co-founder of the company – recently graduated from an apprenticeship with a high-profile leatherworker. Her techniques before were good, but her new work is downright amazing. Best of all, her prices are exceptionally reasonable – considerably less than any luxury label of similar quality, and certainly much less than any bespoke producer.

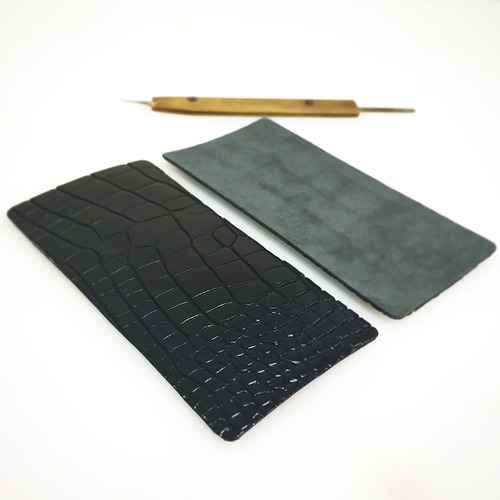

So, I commissioned a custom, black alligator eyewear sleeve. The leather she used is great – supple and soft, it has the flexibility needed for this sort of case, as well as the clean, even scales that distinguishes a good hide from a bad one. From here, the process of making the sleeve is fairly simple and straightforward, but there’s also a lot to the technique.

The most important thing, of course, is to cut the leather in a way that helps the design. Bellanie cut just above the center of the hide, which allows some small scales to be at the non-opening side of the case, before then smoothly transitioning to bigger scales as you go up to the top. Think of it as a gradation effect.

Next, Alcantara is attached to the backside, so as to make the interior soft enough for eyewear (Alcantara, incidentally, has thus far proven to be a lot better than my suede-interior cases, as my sunglasses slide in much more smoothly). The leather is then punched with an awl, in order to prepare it for saddle stitching. Such stitching is not only more durable than machine stitching, but it also gives that inimitable, slightly-angled stitching pattern that can only be produced by hand.

Finally, once stitched, the edges are then burnished and painted in order to protect the leather and give it a more pleasing finish. From the side view, you can hardly tell where the two leathers meet.

So, three years after seeing Simon’s sleeve, I finally have mine. It’s slim enough to slip into a jacket pocket, but also protective enough to keep sharp objects from scratching my lenses. If you ever have a design idea you want executed at a reasonable price, Chester Mox can probably produce it for you. As usual, it’s good to know people who make things.

(pictured: custom eyewear sleeve and card case by Chester Mox, money clip by Elsa Peretti for Tiffany & Co, browline sunglasses by Ray Ban, and pocket square by Christian Kimber)