Pitti Uomo is the twice-a-year menswear tradeshow in Florence, Italy, where industry buyers and sellers meet so they can coordinate their seasonal offerings. But at last month’s Pitti Uomo, there was a strange and unexpected booth. It was nearly all white, had angular shelves, and showcased a new line of ready-to-wear shoes. Above the display, a printed banner read, “Foster & Son.”

For the last hundred years, London’s bespoke tailoring and shoemaking trades have prided themselves on being different from ready-to-wear. Many companies took great pains to explain how custom-clothing is superior to factory production. Additionally, the Savile Row Bespoke Association tried, albeit unsuccessfully, to guard who can use the term bespoke. But in the last ten years, there’s been a shift. Many of London’s best bespoke firms are now using the craft side of their business to give their ready-to-wear lines a halo — something Parisian haute couture houses have been doing for decades.

The venerable firm Foster & Sons has carried the grand tradition of bespoke shoemaking since 1840. They’re part of a small group of custom shoemakers located on the West End, sitting alongside names such as John Lobb and George Cleverley. During England’s medieval period, London was split into two halves. There was the proper city of London on the east, which was a center for finance, banking, and law. Then the City of Westminster on the west. When King Henry VIII built his new royal palace on St. James in the 16th century, he brought with him his aristocratic following. Wealthy elites were happy to live west of London because the pleasurable countryside was usually upwind of the smoke drifting from the crowded City. Over time, as money poured into the area, the West End became known for all the things associated with British aristocratic life — shopping, leisure, gentlemen’s clubs, government, and bespoke shoemaking.

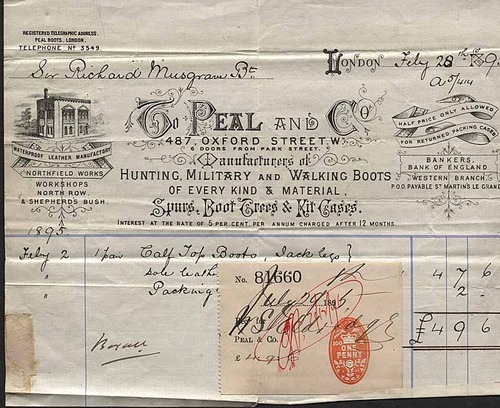

Among the West End shoemakers, Foster & Son is best known for being the most direct successor to Peal, once the largest and most well-known bespoke shoemaking firms. Peal was a pioneer in the “traveling bespoke” business model. By the mid-20th century, they built a clientele list that stretched throughout North and South America, Europe, and East Asia. Sales reps traveled abroad to meet with men, measure and trace their feet, and then take their orders. These notes were then posted to Peal’s factory back in Acton Vale, London, and the polished shoes were delivered six weeks later. This “traveling bespoke” system was so successful that, by the time of the company’s closing, two-thirds of Peal’s production went for export.

Their client list was impressive. There was the regular run of Hollywood stars (Fred Astaire, Humphrey Bogart, Cary Grant, Douglas Fairbanks, Henry Fonda, Steve McQueen, etc.); industrialists such as Henry Ford; intellectuals such as Hugh Trevor-Roper; politicians such as John F. Kennedy; and almost every diplomat, aristocrat, and king from that period. It’s hard to imagine this many people ordering bespoke shoes from just one firm today. Peal was also an important innovator. They developed a system whereby a handmade last could be duplicated up to eight times on a copying lathe. An important innovation, I imagine, given the massive demand.

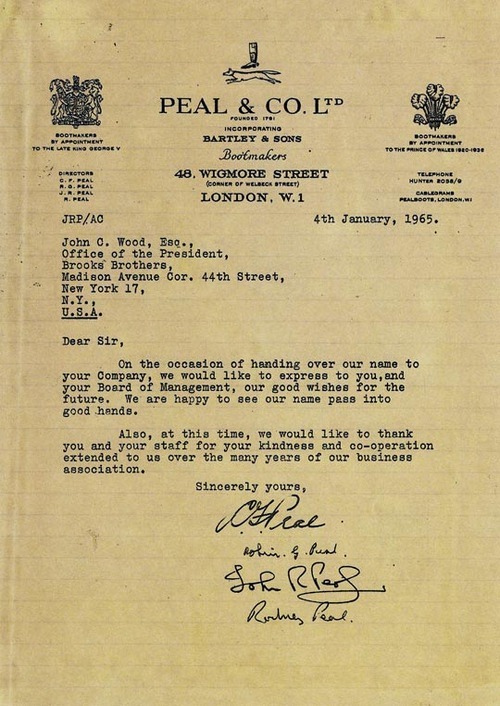

Unfortunately, by the mid-20th century, the company struggled to find suitable replacements for their skilled craftsmen. This led to longer delivery times and, sadly, eventually the closing of the factory in 1965. The trading name was then sold to Brooks Brothers. You can see the letter sealing this agreement above.

Brooks Brothers still trades its shoes under the Peal & Co. banner, but of course, all this history has been forgotten. Their shoes today are made by various English and Italian firms. Peal still somewhat lives on through Foster & Son, however. When the Peal closed, their bespoke last maker, Terry Moore, took many of their lasts with him to Foster & Son, where they’re used today as a valuable reference point. This history is why you can still see Peal’s “boot and fox” emblem in Foster & Son’s signage. It’s the same boot and fox, you’ll notice, that Brooks Brothers stamps inside of their footwear.

In his 1959 book Nothing but the Best, Thomas Girtin describes a lively London labor market that’s full of skilled craftsmen. Sixty years later, the scenes in that book have almost all but disappeared. Today, many bespoke tailoring houses and shoemaking firms struggle to find head cutters and last makers. Whereas there used to be enough tailors on Savile Row to fill the surrounding pubs after working hours, today the trade is much smaller and lonelier. Meanwhile, the cost of labor and rent is going up.

Simon Cundy, who co-owns one of Savile Row’s original tailoring houses, Henry Poole, says skyrocketing rents are squeezing many bespoke firms. “Companies you think would be doing fine, behind the scenes they’re not so fine,” he says. “When our lease came up, we were initially asked to pay 70% higher in rent, but we talked the landlord down. It was a tough moment and adjustments had to be made.” In the last five years, some Savile Row firms have seen their rents double or triple, going well past what’s charged on Bond Street. Henry Poole, founded in 1806, holds 48 royal warrants and has tailored for the likes of Winston Churchill and Napoleon. If not protected, some of Savile Row’s centuries-old firms could be snuffed out, which would leave the Golden Mile with the same fashion brands you can find in any country.

The West End hasn’t been any better. Eight years ago, rents in this part of London hovered around £100 per sq ft. But when business rates were reformed in 2017, some firms saw a rent increase of over 130 percent, according to the regional business association The New West End Company. At these rates, it’s no wonder why so many of London’s leading tailoring and shoemaking firms are moving into ready-to-wear. Handmade items are not scalable — they’re labor-intensive, require rare skill sets, and are sold on a one-off basis. If you want to double your profits, you have to double your production, which means increasing your workforce or labor hours. Ready-to-wear production, on the other hand, can be made much more cheaply and quickly, and then sold around the world with a bit of marketing.

There’s some irony in the fact that so many bespoke firms have had to move into ready-to-wear just so they can keep an address on Savile Row or in the West End, which is essential in today’s age of “authenticity.” Today, you can find off-the-rack clothing from almost all of the leading Savile Row tailoring firms, including Huntsman, Anderson & Sheppard, and Gieves & Hawkes. Mr. Porter also has no fewer than 45 pairs of ready-to-wear shoes from George Cleverly, more than the entire line up of many high-end brands.

Foster & Sons’ new line, however, is unique. While the company has been offering ready-to-wear shoes since the 1970s, in addition to their bespoke service, they recently acquired their own Northampton factory. This new factory gives them total control over their own production (in the past, Crockett & Jones manufactured Foster’s ready-to-wear line). Their new lasts were made in-house by their lastmaker, Simon Bolzoni, and then graded up and down for the different sizes. At the factory, there are also a couple of people who used to work at Edward Green.

This seems like a significant move for a traditional craft-based business. Running a bespoke shop is very different from running a ready-to-wear brand, and having your own factory means dealing with new costs. However, when I talked to Fosters’ retail manager Andrew Murphy, he seemed unconcerned. Foster, he says, is committed to making the best shoes in both bespoke and ready-to-wear. He anticipates that having control over the full production will allow them to offer a superior product, which he believes will be warmly received in discerning markets such as Japan. He also says the company has no plans for manufacturing for anyone but themselves, unlike other Northampton factories.

The good news is that, on paper, the shoes look excellent. They’re made from full-grain leathers, feature leather stiffeners (rather than the more common Celastic), and have carefully cut, beveled waists. The lasts are beautifully shaped with either an almond or a soft chiseled toe. The company also uses just the right pitch of mid-brown without any of the red undertones you sometimes see in other lines (those warmer hues can be harder to wear with the cooler greys and blues that dominate men’s wardrobes). Their Burford loafer is the closest alternative I’ve seen to Edward Green’s Picadilly, which for me is the Platonic ideal of a penny loafer. The Keble is a Norwegian split-toe with a handsewn, pie-crust apron and seamless back counter, the second being a detail typically only seen in bespoke. It also looks like a good alternative to the iconic Dover.

Prices aren’t inexpensive, but starting around $775 for non-slippers, they’re also in a sweet spot. In the last few years, the entry-level end of the market has become intensely competitive with brands such as Meermin, Löf & Tung, and Grant Stone. Meanwhile, companies such as Crockett & Jones, Vass, and Enzo Bonafé continue to dominate the tier above. Foster & Son’s new line is poised to compete in that mid-market, offering people a little bit of handwork for hand grade prices. If London’s bespoke firms have to move into ready-to-wear, at least we can happy the products are good. Who knows, with enough time, maybe we’ll see more bespoke names at Pitti Uomo.